a: Experience method: A rule of thumb is often a useful […]

a: Experience method:

A rule of thumb is often a useful way to solve a problem. It tinkers with reference to the progress of others or one's own.

b: Investigation method:

Some problems with plastic injection molds can only be solved by careful investigation and finding out the change of the station. Repair of crush injuries is a manifestation of this method, but some problems are not as obvious as crush injuries. If you rely solely on experience, you may not find the basis for the problem. Therefore, we must carefully investigate the changes in the strip and injection Helmet Visor Mould in order to really achieve the purpose of the investigation method.

c: Comparison method

Some parts are more complicated. When the scale is not good, it is difficult to judge which station has a problem, so it is necessary to compare the strip of this injection mold with other molds, or compare the current strip with the normal production strip. Compare, find out the difference, and then prescribe medicine to treat the disease. When the scale is not good, the real cause of the problem can be quickly found by comparing the various forming stations.

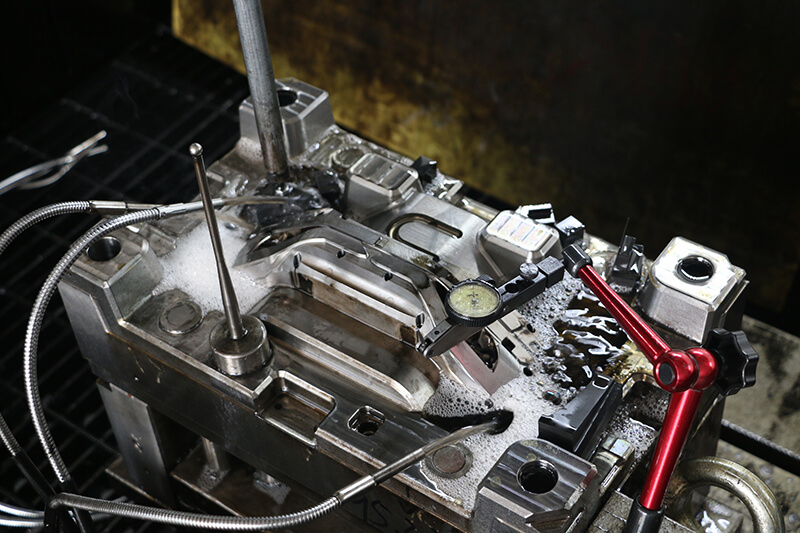

d: Measurement method:

When repairing molds, it is sometimes encountered such a phenomenon that there may be several stations that can cause a certain scale of failure or deformation. After measuring each station, we found the problem. This is how to measure. First, take slow measurements at various locations on the strip to find where the changes are. If this method is used, the defects of the multi-station blanking or the size of the forming position can be repaired.

Taizhou Huangyan Chuangji Mould Industry Co.,Ltd.