Using injection molding to produce automotive accessori […]

Using injection molding to produce automotive accessories mould parts is an effective way to produce a range of different plastic parts. The process uses a custom-made mold to fill the mold with a liquid plastic, which then hardens into the final component. This is a more efficient method than other plastic manufacturing processes, producing parts with high quality and accuracy.

Automotive injection molding is commonly used for dashboards, door handles, and headlight covers, among other car parts. These parts are made from a variety of materials, including ABS and other thermoplastics. A high-quality plastic injection mold can also mould other materials, including metal. These injection molded parts are lightweight and cost effective, making them a preferred choice for automakers. The process allows for mass production of these complex components.

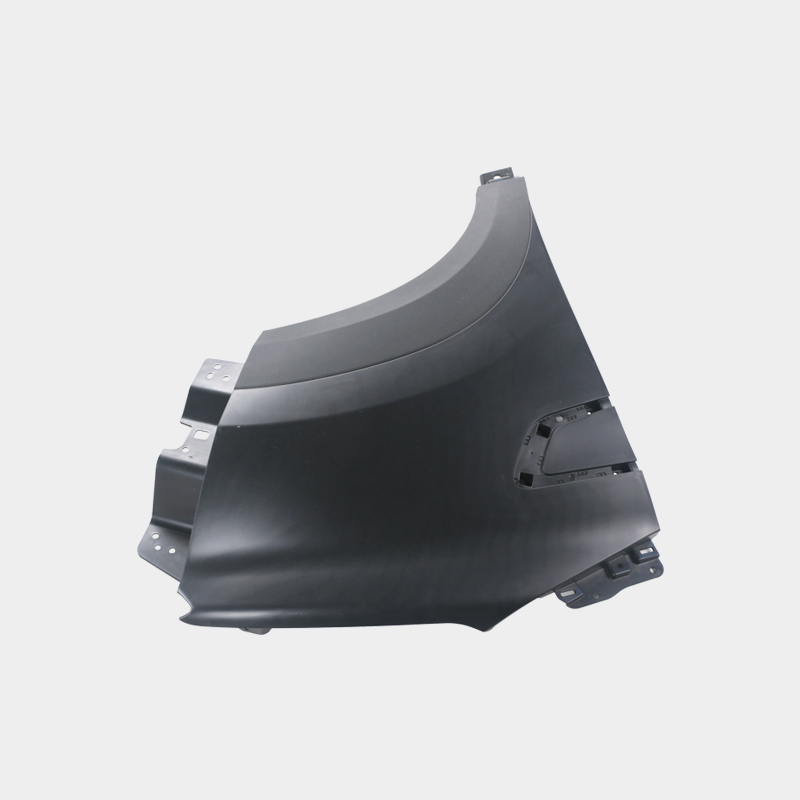

Automotive plastic injection molding also produces a variety of other car parts, including bumpers, headlamps, and intake manifolds. In the early 2000s, plastic structural components began to replace metal counterparts, making car interiors lighter and more fuel-efficient. These components are also used for decorative automotive moldings in luxury cars.

The process of injection molding has been around for more than a century, but it has recently gained new popularity in the automotive industry. The process is used for creating a wide range of parts, from small electrical kits to complex parts like dashboards. It is a reliable method of producing solid plastic parts, and it allows manufacturers to customize colors and other properties. This process produces a solid coloration that cannot be achieved by other plastic manufacturing processes. Injection molding can also mix dyes with raw material pellets before the process begins, which results in the best possible surface finish for the parts.

Another good example of injection molded parts is splash guards, which help prevent dirt and other road debris from splashing onto the car. The process is effective in preventing the influx of water into the car's engine, and it is a great way to keep the interior of the car clean.

Plastics are also used for interior trim, such as door handles, radio dials, and buttons. Plastic is also used for cylinder head covers, oil pans, and other engine accessories. The material is tough and has good abrasion resistance. In addition, it is lightweight, strong, and chemically resistant. Plastics are also used to make car covers, wheel covers, and other automotive accessories.

Another good example of a plastic injection molded part is a dash board, which is a great alternative to glass. Acrylic is a good choice for this application, as it has high strength and optical clarity. It is also shatterproof. It is also a good choice for 3D printing applications, as it has high stiffness and optical clarity. It also is resistant to UV light.

Other examples of plastic injection molded parts include plastic lens covers, plastic cylinder head covers, and electrical kits. The process is also used to make pocket combs, bottle caps, and wire pools. The molded parts are characterized by their high durability and dimensional accuracy.

Taizhou Huangyan Chuangji Mould Industry Co.,Ltd.