Shorten the processing cycle and improve efficiency. ·R […]

Shorten the processing cycle and improve efficiency.

·Replace the cold runner, so that no handle (nozzle material) is produced, and no need to pulverize.

·Improve product consistency and product quality.

·Improve the appearance of the product.

·Reduce product stress and reduce product deformation.

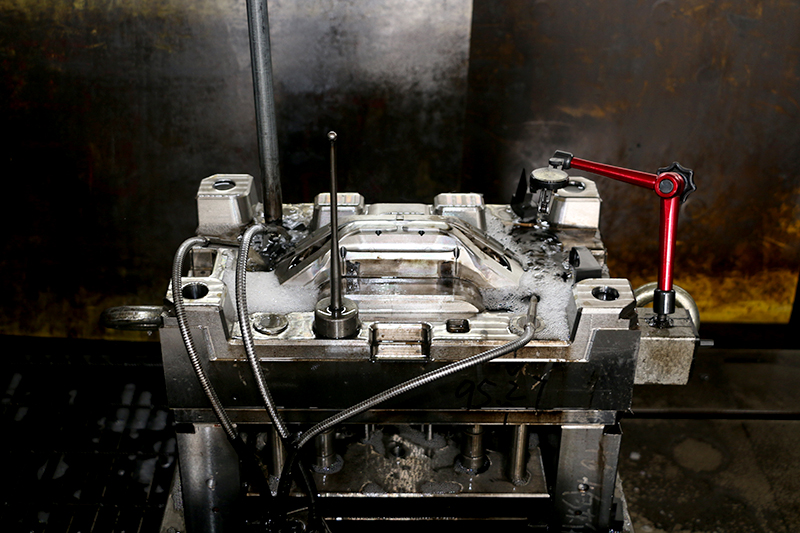

·Adopt valve gate, carry out step-by-step injection Automotive Mould, process and manufacture parts series of different specifications and sizes.

·Provide more process control for precise adjustment of injection molding process.

The embodiment of the key performance elements of the hot runner system:

·Precisely control the temperature of the melt plastic to eliminate material degradation.

·Balanced runner design, the cavity of the parts is evenly filled.

·The proper size of the hot nozzle ensures the smooth flow of the melt and the full filling of the cavity.

·The correct gate structure and size ensure that the cavity is fully filled and the needle valve gate is closed in time, thereby reducing casting and shortening the injection cycle.

·The runner has no dead-angle area, ensuring rapid color change and preventing material degradation.

·Minimize the pressure loss and reduce the clamping force.

·Reasonable holding time.

The correct use of the hot runner system will greatly increase the production efficiency by about 20%-30%, making the molding industry more competitive.

Taizhou Huangyan Chuangji Mould Industry Co.,Ltd.