The products produced by injection Automotive Molds can […]

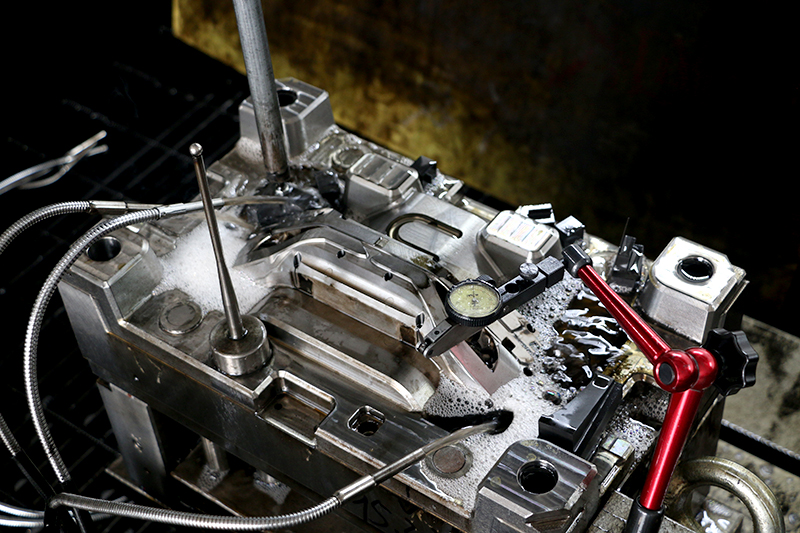

The products produced by injection Automotive Molds can be seen everywhere in our lives, but in fact many people do not understand the processing of injection molds.

The driving force and driving force for the processing and movement of the injection mold are provided by the power of the processing machine and equipment through the transmission mechanism.

Electromechanical transmission: such as punching machine, friction press, roll forging machine, etc., driven by motor, rotating transmission mechanism, connecting the sliding block and the moving parts of the mold, driving the direction movement of the mold, and transmitting the driving force acting on the mold during the forming process Shape the mold.

Electro-hydraulic drive: The jet motor drives the hydraulic pump or water pump to generate hydraulic and water pressure. Through the hydraulic transmission and control system of the liquid, a certain rated pressure is generated to drive the hydraulic cylinder or piston connected with the moving parts of the mold (such as the moving mold), thereby driving the moving mold to move relative to the direction of the fixed mold and further compress the material. materials are processed into finished products.

Air pressure molding: mainly used for suction blow molding, that is, when the mold is in a fixed state, the plastic sheet is directly sucked by the air pump and pasted on the surface of the mold to form parts. In addition, injection mold processing drives, such as aluminum alloy profiles, plastic profiles, sheets or films, are generally used for extrusion processing. The die is attached to the die, and the material is extruded through the die and moved relative to the die.

Taizhou Huangyan Chuangji Mould Industry Co.,Ltd.