The application range of plastic products is constantly […]

The application range of plastic products is constantly expanding, such as: household appliances, instrumentation, construction equipment, automobile industry, daily hardware and other fields, and the proportion of plastic products is increasing rapidly. These various products are produced through plastic molds.

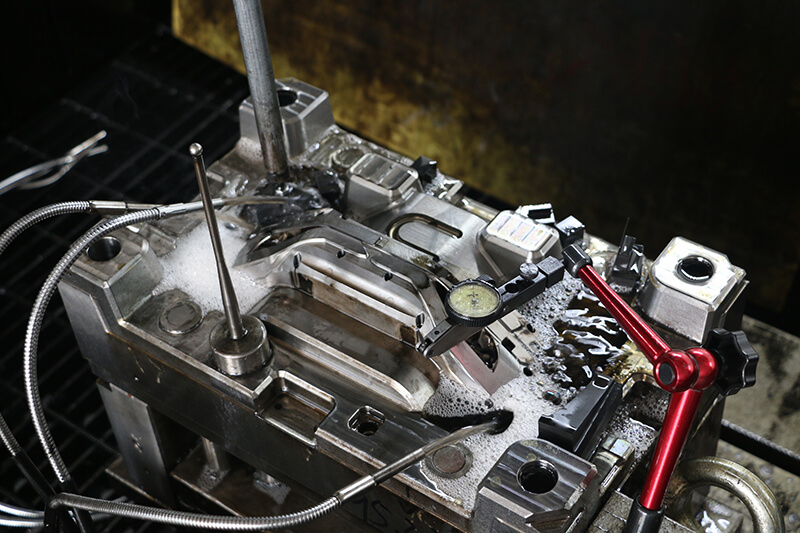

Moulds are tools used to produce plastic products. It consists of several groups of parts with cavities. In the injection molding process, the mold is clamped on the injection molding machine, the molten plastic is injected into the mold cavity, formed in the cavity, and then the upper mold and the lower mold are separated, and the product is discharged from the mold. The cavity leaves the mold through the ejection system and the mold closes. For the next injection, the entire injection molding process is cyclic.

Mold meets process performance requirements

The mold is usually manufactured by forging, cutting, heat treatment and other processes. In order to ensure the quality of the Automotive Mold and reduce production costs, the material should have good forgeability, machinability, hardenability, hardenability and grindability; it should also have small oxidation, decarburization sensitivity and quenching deformation cracking tendency.

Mold meets economic requirements

When choosing a mold, economic principles must be considered to reduce manufacturing costs as much as possible. Therefore, under the premise of satisfying the performance, the price is lower first, carbon steel may not use alloy steel, and domestic materials may not use imported materials.

Taizhou Huangyan Chuangji Mould Industry Co.,Ltd.